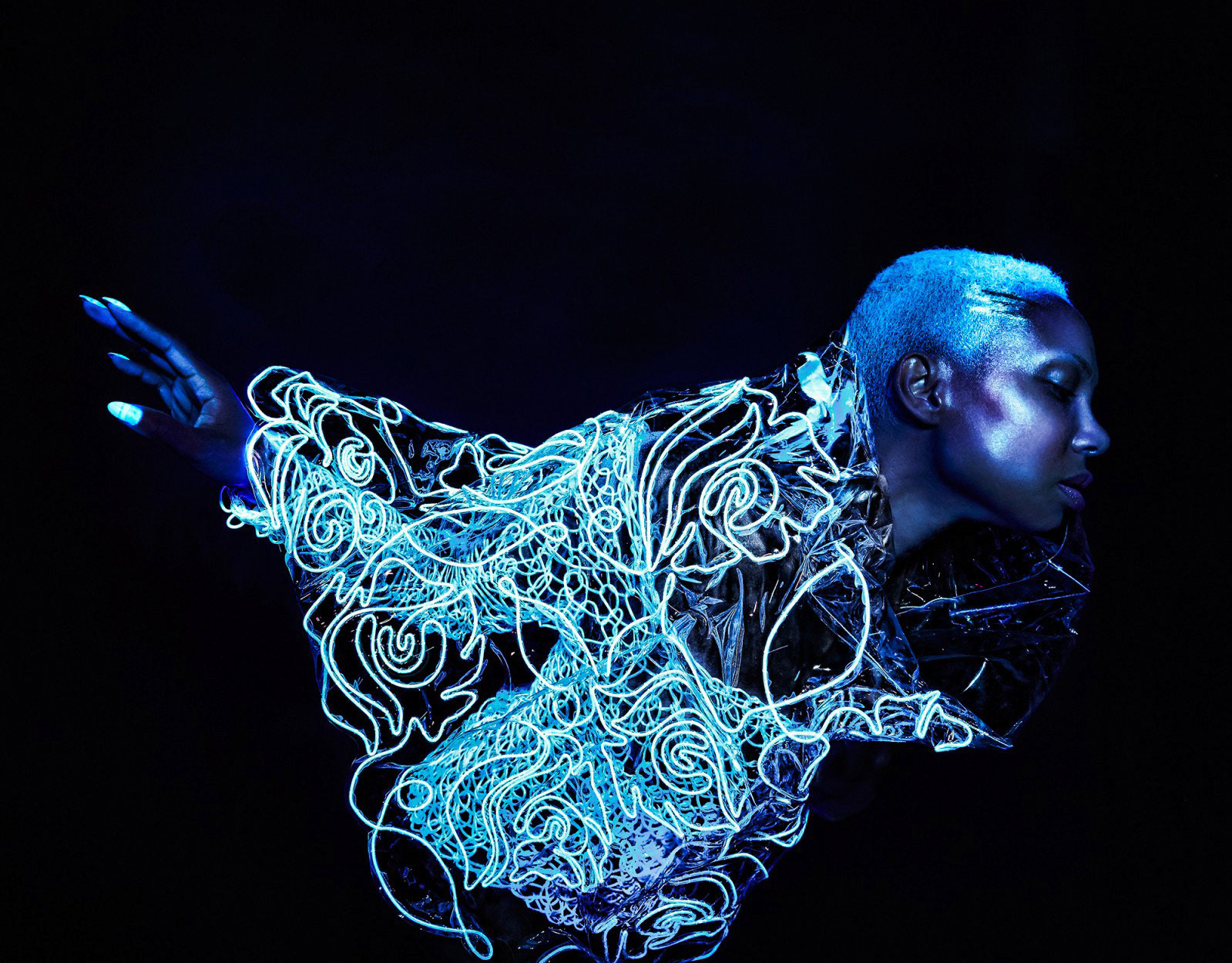

Knit EL Wire Dress

2016

Team Capybara

2016

Cheating at Street Fighter IV with an Arduino

2015